Why Pulley Lagging Is Essential for Conveyor Systems

2025-08-27

In modern industrial operations, conveyor systems are the backbone of productivity, ensuring smooth and efficient material handling. However, one often-overlooked component that plays a critical role in the performance and durability of these systems is pulley lagging. Whether you operate in mining, cement, steel, power generation, or bulk material handling, the right pulley lagging solution can significantly improve traction, extend pulley lifespan, reduce maintenance costs, and enhance operational efficiency.

What Is Pulley Lagging and Why Does It Matter?

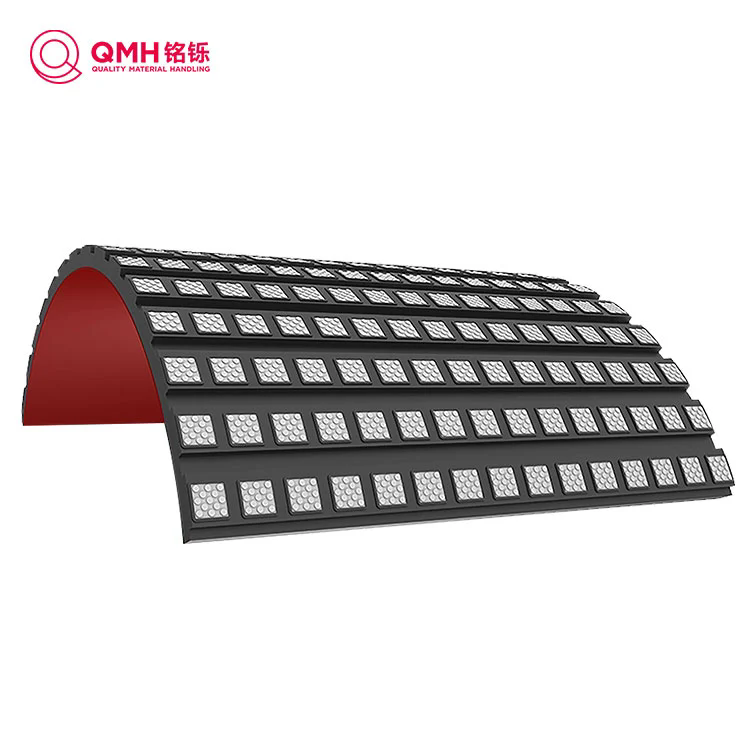

Pulley lagging refers to the application of a protective layer—typically rubber, ceramic, or a combination of both—on the surface of conveyor pulleys. This layer enhances friction between the pulley and the conveyor belt, prevents slippage, and protects the pulley from wear and tear caused by constant contact with abrasive materials.

Without proper pulley lagging, conveyor systems are prone to belt slippage, premature wear, increased downtime, and reduced efficiency. By contrast, investing in high-quality lagging solutions ensures:

-

Increased Traction → Better grip between the pulley and belt minimizes slippage.

-

Reduced Belt Wear → Less frictional heat and mechanical stress extend belt life.

-

Enhanced Pulley Protection → Lagging acts as a shield, reducing surface wear and corrosion.

-

Lower Maintenance Costs → Less downtime and fewer replacements mean higher productivity.

-

Optimized Power Transmission → Improved efficiency translates into significant energy savings.

Types of Pulley Lagging

Choosing the right pulley lagging depends on your operational environment and application requirements. Below are the most widely used types:

| Type | Material | Surface Pattern | Applications | Advantages |

|---|---|---|---|---|

| Rubber Lagging | Natural/Synthetic Rubber | Diamond, Plain, Herringbone | General conveyors, moderate wear conditions | Cost-effective, good grip, easy installation |

| Ceramic Lagging | Ceramic Tiles Embedded in Rubber | Smooth or Tile Pattern | Mining, heavy-duty, high-tension belts | Superior traction, high abrasion resistance |

| Strip Lagging | Rubber Strips | Parallel Grooves | Low-speed conveyors, wet conditions | Improved drainage, better wet grip |

| PU Lagging | Polyurethane | Smooth or Diamond | Food, chemical, and pharmaceutical sectors | Non-marking, chemical-resistant, hygienic |

How Does Pulley Lagging Improve Conveyor System Performance?

The primary purpose of pulley lagging is to enhance the coefficient of friction between the pulley surface and the conveyor belt. Without sufficient traction, belts tend to slip, resulting in uneven load distribution, misalignment, and accelerated wear.

Key Functions of Pulley Lagging:

-

Prevents Belt Slippage

Pulley lagging materials, especially ceramic or diamond-patterned rubber, provide excellent grip. This stabilizes belt movement, even under heavy loads or wet, muddy conditions. -

Protects Pulley Shell

Continuous exposure to abrasive materials, moisture, and chemicals can corrode or erode pulley shells. Lagging acts as a protective barrier, extending the service life of expensive pulley components. -

Enhances Belt Tracking

Proper lagging reduces misalignment issues, ensuring the belt runs centrally and evenly. This minimizes the chances of belt edge damage and spillage. -

Energy Efficiency

Reduced slippage means less wasted energy. Conveyor systems require less power to operate efficiently, leading to long-term energy savings. -

Minimizes Downtime

Unplanned maintenance or belt replacements cost valuable operational time. High-quality lagging ensures consistent, predictable performance, keeping production schedules on track.

Selecting the Right Pulley Lagging for Your Application

Choosing the right lagging solution depends on several factors, including material characteristics, operational conditions, and system requirements. Here are key considerations:

A. Environmental Conditions

-

Wet and Muddy Conditions → Ceramic or herringbone rubber lagging ensures better drainage and grip.

-

Dry and Dusty Conditions → Diamond-patterned rubber provides optimal traction.

-

Corrosive or Chemical Environments → Polyurethane or specially formulated chemical-resistant lagging is ideal.

B. Belt Speed and Tension

-

High-speed or high-tension systems require ceramic lagging for its superior wear resistance.

-

Low-speed conveyors with minimal tension can use cost-effective rubber lagging.

C. Material Handled

-

Abrasive Materials → Ceramic lagging provides excellent durability.

-

Bulk, Light Materials → Rubber lagging offers sufficient performance at a lower cost.

D. Maintenance Preferences

-

Vulcanized lagging provides better adhesion and durability but requires professional installation.

-

Cold-bonded lagging is easier and faster to install but may require more frequent replacement.

Product Specifications and Technical Data

For industrial customers seeking reliable performance, QMH offers a comprehensive range of pulley lagging solutions tailored to specific operational needs.

| Specification | Rubber Lagging | Ceramic Lagging | PU Lagging |

|---|---|---|---|

| Thickness | 8mm, 10mm, 12mm, 15mm | 12mm, 15mm, 20mm | 8mm, 10mm |

| Hardness (Shore A) | 55 ± 5 | 60 ± 5 | 65 ± 5 |

| Surface Patterns | Diamond / Herringbone | Ceramic Tile / Smooth | Smooth / Diamond |

| Temperature Resistance | -20°C to +80°C | -20°C to +120°C | -30°C to +90°C |

| Tensile Strength | ≥ 12 MPa | ≥ 18 MPa | ≥ 15 MPa |

| Applications | General material handling | Mining, cement, steel | Food & chemical industries |

These specifications ensure our pulley lagging solutions deliver optimal traction, maximum protection, and extended service life across a variety of industrial environments.

Pulley Lagging FAQs

FAQ 1: How often should pulley lagging be replaced?

Pulley lagging replacement frequency depends on factors like operating conditions, belt tension, and material abrasiveness. In high-abrasion environments such as mining, lagging may need replacement every 12–18 months. In less demanding applications, quality rubber lagging can last up to 3–5 years. Regular inspections are essential to identify early signs of wear, cracking, or detachment.

FAQ 2: Is ceramic pulley lagging worth the extra cost?

Yes. Although ceramic lagging has a higher upfront cost, it delivers exceptional durability and improved traction, especially under wet, muddy, or high-tension conditions. In heavy-duty industries, ceramic lagging significantly reduces downtime and replacement costs, making it a cost-effective investment over the long term.

Why Choose QMH for Pulley Lagging Solutions

Optimizing your conveyor system’s efficiency starts with choosing the right pulley lagging solution. From reducing belt slippage and preventing premature wear to extending the lifespan of your equipment, high-quality lagging directly impacts productivity and profitability.

QMH is a trusted provider of premium pulley lagging solutions designed for industries like mining, cement, steel, power, and bulk handling. Our products are engineered with precision, tested under rigorous conditions, and backed by expert technical support to ensure unmatched performance.

Whether you need rubber, ceramic, or polyurethane lagging, QMH delivers solutions tailored to your operational requirements. Enhance your conveyor performance, reduce downtime, and protect your investment with our world-class pulley lagging products.

Contact us today to discuss your application needs and get customized solutions that keep your operations running efficiently.