What Makes the 110-315 HDPE Pipe Extrusion Line a Reliable Solution for Versatile Pipe Production?

2025-06-18

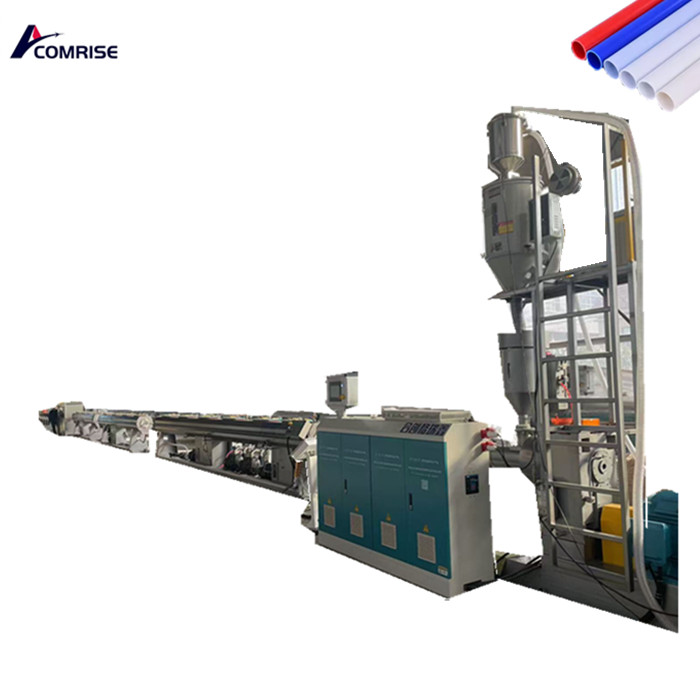

The 110-315 HDPE pipe extrusion line is a high-performance production system designed to manufacture a wide range of polyethylene (PE) pipes, including HDPE, LDPE, and general PE materials. Engineered for durability, precision, and efficiency, this extrusion line supports pipe diameters ranging from 110 mm to 315 mm and is suitable for various wall thicknesses to meet the requirements of agricultural, industrial, and municipal applications. Whether used for water supply, drainage systems, or construction projects, this extrusion line offers reliable and consistent output that complies with international standards such as ISO9001, GB, and DIN.

This advanced PE pipe production line is composed of several core components: a single-screw extruder, vacuum calibrator, haul-off tractor, precision cutting machine, and a self-dumping rack. Each component plays a crucial role in maintaining the structural integrity and dimensional accuracy of the finished pipes. The single-screw extruder ensures stable melting and extrusion of the raw material, while the vacuum calibrator shapes the pipe and maintains roundness during cooling. The haul-off tractor provides synchronized pulling force, and the cutting machine delivers clean and accurate cuts according to specified lengths. Finally, the self-dumping rack enables efficient handling and stacking of finished products.

The pipes produced by the 110-315 HDPE extrusion line meet working pressures between 0.6 MPa and 1.6 MPa, making them suitable for medium-pressure applications. These pipes are widely adopted across numerous industries, including water and gas supply, electrical cable protection, agricultural irrigation, construction engineering, and even home appliances such as washing machines and ventilation systems. In specialized sectors, PE pipes are also used for automotive wiring, lamp casing protection, and machine tool fluid circuits due to their excellent chemical resistance, lightweight structure, and ease of installation.

For manufacturers seeking a reliable and versatile pipe production solution, the 110-315 HDPE pipe extrusion line offers outstanding performance, flexibility in pipe specifications, and broad application potential—all backed by stable mechanical operation and long service life. Whether for infrastructure development or industrial manufacturing, this line delivers the quality and efficiency needed to stay competitive in today’s market.