Unveiling the Environmental Impact of Aluminum Sheet Stamping Versus Other Metal Forming Techniques

2024-04-17

In the realm of metal fabrication, the environmental footprint of various processes is a crucial consideration. As sustainability takes center stage in global conversations, industries are seeking ways to minimize their impact on the environment. Among these processes, aluminum sheet stamping stands out as a versatile and widely used method. But how does it fare in terms of environmental sustainability when compared to other metal forming techniques? Let's delve deeper into this question.

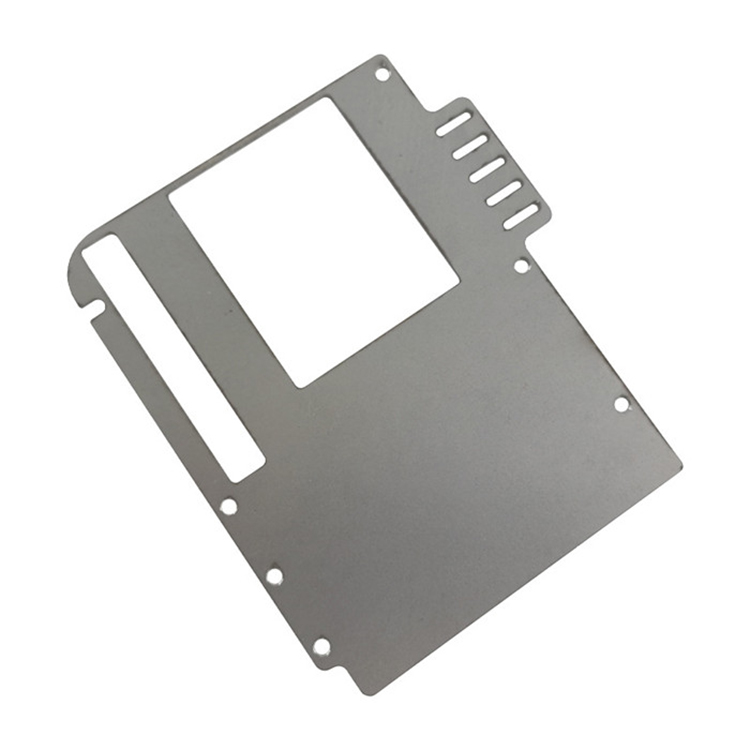

Understanding Aluminum Sheet Stamping

Aluminum sheet stamping involves the shaping and forming of aluminum sheets through a stamping press and a die. This method is renowned for its efficiency in producing intricate and precise shapes, making it indispensable in industries ranging from automotive to aerospace.

Environmental Considerations

Energy Consumption

Energy consumption is a significant aspect of any manufacturing process. Aluminum sheet stamping typically requires substantial energy inputs, particularly for operating stamping presses and other machinery. However, advancements in technology have led to the development of more energy-efficient equipment, helping to mitigate this impact.

Compared to other metal forming techniques such as casting or forging, aluminum sheet stamping often consumes less energy per unit of production. Casting, for instance, involves melting metal at high temperatures, which demands considerable energy. Meanwhile, forging necessitates intense heat and pressure, contributing to higher energy requirements.

Material Efficiency

Aluminum is renowned for its recyclability, with approximately 75% of all aluminum ever produced still in use today. This inherent property lends aluminum sheet stamping an advantage over other metals. The ability to recycle scrap aluminum significantly reduces the need for primary production, conserving resources and minimizing environmental degradation.

In contrast, certain metal forming techniques, such as casting, may generate more waste material due to the removal of excess metal during finishing processes. While recycling is feasible for many metals, the efficiency and feasibility vary depending on factors like purity and contamination.

Emissions and Waste

Emissions and waste generation are critical indicators of environmental impact. Aluminum sheet stamping, when compared to techniques like welding or machining, generally produces fewer emissions and waste. Welding, for instance, often involves the use of shielding gases and generates fumes, contributing to air pollution. Machining operations can generate significant amounts of metal shavings and waste materials.

Aluminum sheet stamping, with its precision forming capabilities, minimizes material wastage and reduces the need for secondary machining operations, thereby decreasing overall waste generation.

Conclusion

In the quest for sustainable manufacturing practices, the environmental impact of metal forming techniques cannot be overlooked. While aluminum sheet stamping entails energy consumption and resource utilization, its inherent advantages in material efficiency, emissions, and waste reduction position it favorably compared to other methods.

Moreover, ongoing advancements in technology and process optimization continue to enhance the environmental performance of aluminum sheet stamping, making it a compelling choice for industries striving for sustainability.

As we navigate the complex landscape of metal fabrication, it's imperative to consider not only the technical aspects but also the environmental implications. By choosing processes that prioritize efficiency, resource conservation, and waste reduction, we can forge a path towards a more sustainable future for generations to come.