Unveiling Brilliance: How the Brushing Process Works with Diamond Wheels Brushed Bronze

2024-03-21

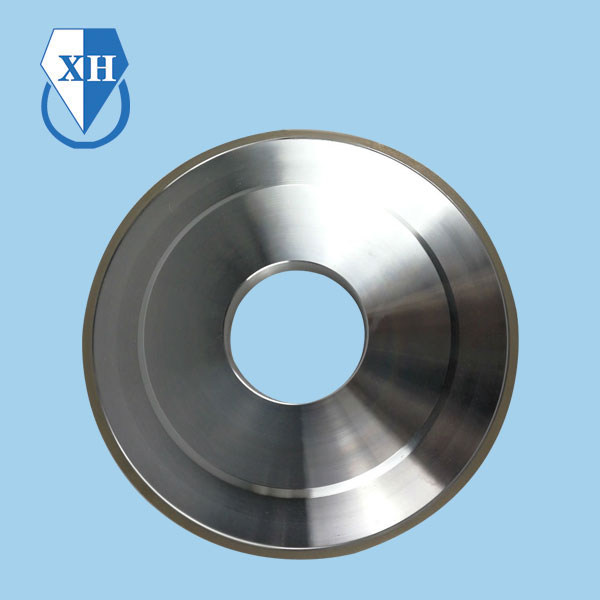

In the realm of precision machining and surface finishing, achieving impeccable results requires the use of advanced tools and techniques. Among these, diamond wheels brushed bronze stand out as a sophisticated choice for imparting exquisite surface finishes and intricate textures to machined components. But how does the brushing process work with diamond wheels brushed bronze, and what makes it such an effective method for enhancing the aesthetic appeal of finished products? Let's delve into the intricacies of this fascinating process.

1. Understanding Diamond Wheels Brushed Bronze:

Before delving into the brushing process, it's essential to understand the components involved. Diamond wheels brushed bronze combine the exceptional hardness of diamond particles with the aesthetic appeal of brushed bronze finishes. These specialized abrasive tools are designed to cut through hard and brittle materials with precision while imparting a lustrous sheen and textured appearance to the surface of the workpiece.

2. The Brushing Action:

The brushing process involves the use of abrasive filaments or bristles attached to the periphery of the diamond wheel. As the wheel rotates, the abrasive filaments come into contact with the surface of the workpiece, imparting a brushing action that smooths out imperfections, removes burrs, and creates a textured surface finish. This brushing action is gentle yet effective, ensuring uniformity and consistency in the surface finish.

3. Selection of Brushing Parameters:

Achieving the desired surface finish with diamond wheels brushed bronze requires careful selection of brushing parameters, including rotational speed, feed rate, and pressure. These parameters are optimized based on factors such as the material being machined, the desired surface texture, and the specific requirements of the application. By fine-tuning these parameters, machinists can achieve precise control over the brushing process and ensure optimal results.

4. Material Removal and Smoothing:

During the brushing process, diamond particles embedded in the abrasive filaments perform the dual function of material removal and smoothing. The exceptional hardness of diamond ensures efficient material removal, while the brushing action smooths out surface irregularities and creates a uniform texture. This combination of cutting and brushing results in a surface finish that is both visually appealing and tactilely satisfying.

5. Enhancing Aesthetic Appeal:

One of the key benefits of the brushing process with diamond wheels brushed bronze is its ability to enhance the aesthetic appeal of finished products. The textured surface finish created by the brushing action adds depth, dimension, and visual interest to machined components, transforming them from ordinary to extraordinary. Whether used in architectural applications, luxury goods manufacturing, or high-end consumer products, the brushed bronze finish exudes sophistication and elegance.

6. Versatility Across Materials:

Another advantage of the brushing process with diamond wheels brushed bronze is its versatility across a wide range of materials. From metals and ceramics to glass and composites, diamond wheels can achieve consistent and reliable results on diverse substrates. This versatility makes them suitable for surface finishing applications in various industries, from aerospace and automotive to jewelry and electronics.

7. Quality and Consistency:

Consistency is key in surface finishing applications, and the brushing process with diamond wheels brushed bronze delivers consistent results batch after batch. By controlling parameters such as rotational speed, feed rate, and pressure, machinists can ensure uniformity and reproducibility in the surface finish, meeting the highest quality standards and customer expectations.

In conclusion, the brushing process with diamond wheels brushed bronze offers a unique combination of precision, versatility, and aesthetic appeal in surface finishing applications. By harnessing the cutting-edge technology and craftsmanship behind diamond wheels brushed bronze, manufacturers can elevate the quality, value, and marketability of their products, turning ordinary components into works of art.