Understanding the Impact of Wind Load and Atmospheric Conditions on Steel Chimney Integrity

2024-04-11

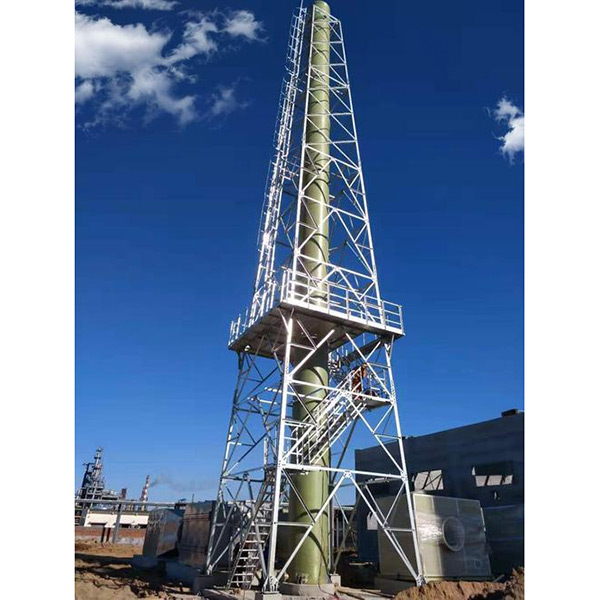

Steel chimneys stand tall as iconic structures in industrial landscapes, serving vital functions in exhausting gases and maintaining air quality. Yet, their towering presence also makes them susceptible to various environmental factors, notably wind load and atmospheric conditions. Understanding how these factors impact the structural integrity of steel chimneys is essential for ensuring their safety and longevity.

The Influence of Wind Load

1. Force Exertion: Wind load refers to the pressure exerted by wind on the surfaces of a structure. Steel chimneys, with their slender profiles and significant height, are particularly susceptible to wind forces. The magnitude of wind load depends on factors such as wind speed, direction, and the shape of the chimney.

2. Dynamic Response: Wind-induced vibrations can cause dynamic responses in steel chimneys, leading to oscillations and potential fatigue failure. Engineers must carefully consider the dynamic characteristics of the chimney, including its natural frequency and damping properties, to mitigate the effects of wind-induced vibrations.

3. Design Considerations: Designing a steel chimney to withstand wind load involves factors such as structural stiffness, aerodynamic shape, and the use of wind-reducing features such as strakes or helical strakes. By optimizing these design parameters, engineers can enhance the chimney's resistance to wind forces and minimize the risk of structural failure.

Impact of Atmospheric Conditions

1. Corrosion Risk: Atmospheric conditions, including humidity, temperature variations, and airborne pollutants, pose a significant corrosion risk to steel chimneys. Corrosion can weaken the structural integrity of the chimney over time, making it more susceptible to wind-induced damage.

2. Material Degradation: Exposure to atmospheric conditions can accelerate material degradation in steel chimneys, particularly in harsh environments such as coastal areas or industrial zones with high levels of pollutants. Protective coatings and regular maintenance are essential for mitigating corrosion and preserving the structural integrity of the chimney.

3. Temperature Effects: Atmospheric temperature fluctuations can also impact the structural behavior of steel chimneys. Thermal expansion and contraction of the chimney's materials can induce stresses and deformation, potentially compromising its integrity. Proper thermal insulation and expansion joints help minimize the effects of temperature variations on the chimney structure.

Ensuring Structural Integrity

1. Advanced Analysis Techniques: Engineers utilize advanced analysis techniques, including computational fluid dynamics (CFD) and finite element analysis (FEA), to assess the structural response of steel chimneys to wind load and atmospheric conditions. These simulations help optimize design parameters and identify potential failure modes.

2. Regular Inspection and Maintenance: Routine inspection and maintenance are critical for ensuring the ongoing structural integrity of steel chimneys. Inspections should include assessments of corrosion, weld integrity, and overall structural condition, with any defects addressed promptly to prevent further deterioration.

3. Compliance with Standards: Design and construction of steel chimneys must comply with relevant industry standards and codes governing structural integrity, wind resistance, and corrosion protection. Adhering to these standards ensures that chimneys are built to withstand environmental challenges and operate safely throughout their service life.

In conclusion, wind load and atmospheric conditions significantly impact the structural integrity of steel chimneys in industrial settings. By understanding these factors and implementing appropriate design measures, maintenance practices, and compliance with industry standards, engineers can ensure the reliability and safety of steel chimneys, contributing to the efficient operation of industrial facilities and the protection of surrounding environments.