The Versatile Choice: Industries and Applications for Duplex Steel S31803 Threaded Flanges

2024-06-12

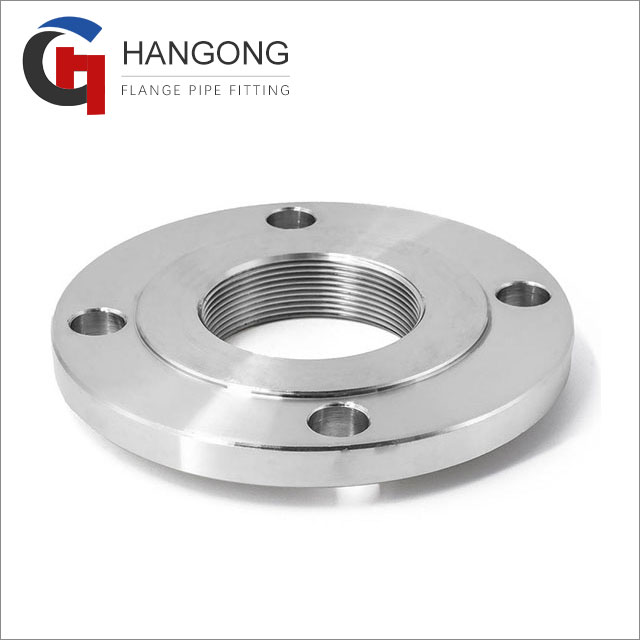

Duplex Steel S31803 Threaded Flanges have become a staple in numerous industries due to their outstanding properties. Combining the best features of austenitic and ferritic stainless steels, Duplex Steel S31803 offers superior corrosion resistance, high strength, and excellent durability. In this blog, we will explore the industries and applications where Duplex Steel S31803 Threaded Flanges are most commonly utilized and explain why they are preferred in these settings.

Key Industries Utilizing Duplex Steel S31803 Threaded Flanges

1. Oil and Gas Industry

Applications:

· Offshore drilling platforms

· Subsea pipelines

· Refineries

· Gas processing plants

Why Preferred:

The oil and gas industry operates in some of the most demanding environments, where components are exposed to high pressures, extreme temperatures, and corrosive substances. Duplex Steel S31803 Threaded Flanges are favored in this industry due to their exceptional resistance to chloride-induced stress corrosion cracking and pitting, as well as their high mechanical strength. These properties ensure reliable performance and longevity in harsh offshore and onshore conditions.

2. Chemical and Petrochemical Industry

Applications:

· Chemical processing equipment

· Acid production plants

· Storage tanks

· Heat exchangers

Why Preferred:

Chemical processing involves the handling of aggressive chemicals that can cause rapid corrosion. Duplex Steel S31803 offers superior resistance to a wide range of corrosive agents, including sulfuric acid, phosphoric acid, and chlorides. This makes it an ideal material for flanges in the chemical and petrochemical industries, where maintaining the integrity of the piping systems is critical to safety and efficiency.

Specific Applications in Various Settings

Heat Exchangers:

Duplex Steel S31803 is commonly used in heat exchangers due to its high thermal conductivity and resistance to thermal fatigue. These properties allow for efficient heat transfer and prolonged service life.

Pressure Vessels:

In industries such as oil and gas and chemical processing, pressure vessels made with Duplex Steel S31803 flanges are preferred for their ability to withstand high pressures and resist stress corrosion cracking.

Piping Systems:

Duplex Steel S31803 flanges are essential components in piping systems that transport aggressive chemicals, seawater, and other corrosive fluids. Their durability and resistance to corrosion ensure the integrity and safety of these systems.

Conclusion

Duplex Steel S31803 Threaded Flanges are a versatile and reliable choice across various industries, including oil and gas, chemical and petrochemical, marine and shipbuilding, pulp and paper, and water treatment and desalination. Their superior corrosion resistance, high strength, and durability make them an invaluable component in applications where reliability and longevity are paramount.

Choosing Duplex Steel S31803 for your threaded flanges ensures that your systems will withstand the rigors of harsh environments, reduce maintenance costs, and enhance overall operational efficiency. This material's unique properties make it a preferred choice for engineers and industry professionals seeking the best performance in demanding applications.