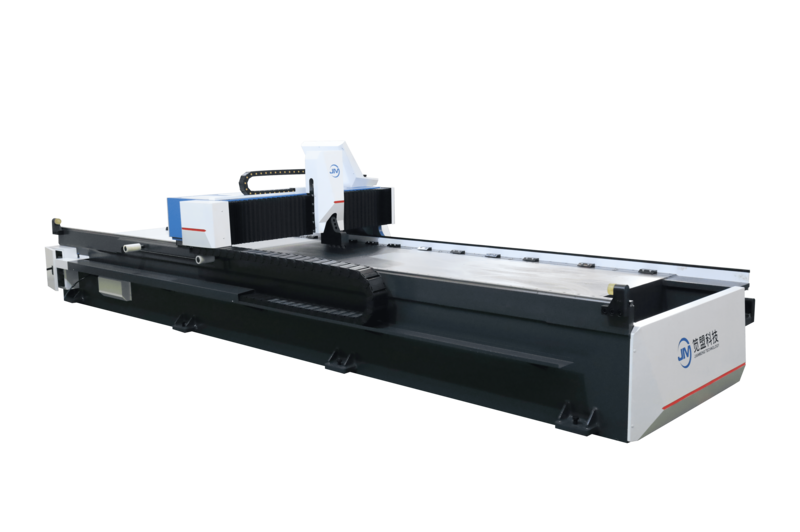

Streamlining Metal Fabrication with the Horizontal V Grooving Machine

2025-02-21

In the world of metal fabrication, precision and efficiency are paramount. Whether you're working with stainless steel, aluminum, copper, or composite materials, achieving clean, sharp grooves is essential for high-quality finishes, especially when it comes to decorative metal applications. One tool that has revolutionized the way professionals approach this task is the Horizontal V Grooving Machine.

JIANMENG, a leading manufacturer from China, specializes in high-quality Horizontal V Grooving Machines designed to meet the precision demands of the sheet metal industry. In this blog, we’ll dive into the capabilities of this innovative machine and how it helps manufacturers streamline the production of intricate, high-end metal works.

What is a Horizontal V Grooving Machine?

A Horizontal V Grooving Machine is a specialized tool used in the sheet metal industry to create precise V-shaped grooves on various types of metal sheets. The grooves are typically used in processes such as bending and shaping, particularly in industries that require high precision, such as architecture, automotive manufacturing, and electronics.

Unlike traditional methods of grooving, which can produce rough edges and imprecise cuts, the horizontal V grooving machine creates clean, well-defined grooves with a very small edge radius. This results in smoother bends, improved structural integrity, and an aesthetically pleasing finish that meets the high standards of the high-end sheet metal decoration industry.

How the Horizontal V Grooving Machine Works

The Horizontal V Grooving Machine operates by using rotating tools to cut grooves into metal sheets in a horizontal direction. The machine is designed to work with various metals, including:

- Stainless Steel Sheets

- Aluminum Sheets

- Composite Aluminum Sheets

- Copper Sheets

- Other Metal Plates

The machine's design ensures that the grooves are consistent and precise, and the grooving process is automated for increased efficiency. The adjustable cutting depth and width allow manufacturers to create grooves that match specific requirements, whether for aesthetic or structural purposes. Once the grooves are made, the metal sheets can be bent without compromising the overall quality or appearance of the material.

Key Benefits of the Horizontal V Grooving Machine

1. High Precision and Accuracy

One of the standout features of the Horizontal V Grooving Machine is its ability to create extremely precise grooves. This is particularly important for industries that demand high accuracy, such as architectural design, where even the smallest error in a groove can affect the final product's fit and appearance. The machine’s advanced technology ensures that every groove is consistent, with a very small edge radius, making it perfect for delicate, high-end metal fabrication.

2. Improved Aesthetic Quality

The clean V-shaped grooves produced by the Horizontal V Grooving Machine not only enhance the functional aspect of the metal sheet but also contribute to the aesthetic quality of the final product. In industries like interior design and high-end metal decoration, appearance matters as much as function. The smooth edges and fine grooves create a polished look that is highly desirable in custom metal fabrication.

3. Cost-Effective and Time-Saving

Thanks to its automation, the Horizontal V Grooving Machine is a significant time-saver compared to manual grooving methods. It reduces labor costs and increases productivity by allowing operators to perform grooving tasks quickly and efficiently. Additionally, the precise nature of the machine reduces material waste, making the process more cost-effective overall.

4. Versatility in Material Handling

JIANMENG’s Horizontal V Grooving Machine is designed to work with a wide range of metal materials, from stainless steel and aluminum to copper and composite sheets. This versatility makes the machine an excellent choice for manufacturers in various industries, including metal fabrication, sheet metal decoration, and architecture.

5. Small Edge Radius for Complex Bending

When working with metal sheets, especially in decorative and structural applications, having a very small edge radius is crucial for ensuring smooth bends without distortion. The Horizontal V Grooving Machine excels in this area, allowing workpieces to be bent precisely without compromising their structural integrity or visual appeal.

6. Ease of Operation and Maintenance

With its user-friendly interface and intuitive controls, the Horizontal V Grooving Machine is easy to operate, even for less experienced workers. Additionally, the machine is designed for low maintenance, ensuring that it runs efficiently for longer periods with minimal downtime.

Applications of the Horizontal V Grooving Machine

1. Metal Decoration and Architecture

The Horizontal V Grooving Machine is widely used in the high-end sheet metal decoration industry, where intricate metal designs are essential. Whether it’s for creating decorative facades, custom sculptures, or detailed metal panels, the precise grooves make it possible to create visually stunning results that meet the aesthetic demands of architects and designers.

2. Sheet Metal Bending

In industries like automotive manufacturing and HVAC systems, metal sheets are often bent to create various components. The grooves created by the Horizontal V Grooving Machine ensure that the bending process is smooth, precise, and clean, without causing material distortion or compromising the quality of the finished product.

3. Custom Metal Fabrication

From custom enclosures and industrial equipment to signage and art pieces, the Horizontal V Grooving Machine allows for highly customized metal fabrication. It provides the flexibility to create grooves in various configurations, making it an invaluable tool for custom metal workers and fabricators.

4. Electronics and Precision Manufacturing

For industries that require highly detailed metal parts, such as electronics and precision engineering, the Horizontal V Grooving Machine’s ability to create fine grooves with minimal edge radius makes it ideal. The precise cuts allow for the creation of components that fit together perfectly without compromising their performance.

Why Choose JIANMENG’s Horizontal V Grooving Machine?

JIANMENG stands out as a professional leader in the manufacturing of Horizontal V Grooving Machines. With years of experience in the metal fabrication industry, JIANMENG offers machines that are not only durable and reliable but also affordable. Their products are designed to make metal fabrication easier by offering high precision, ease of use, and adaptability to various materials.

JIANMENG provides a range of solutions that help manufacturers optimize their production processes, reduce material waste, and achieve the high-quality results demanded by industries across the board. By choosing a JIANMENG Horizontal V Grooving Machine, manufacturers can be assured that they are investing in a tool that enhances both efficiency and quality.

The Horizontal V Grooving Machine is a game-changer for industries that require high-precision metal work, offering excellent functionality, aesthetic value, and cost-effectiveness. Whether you’re working with stainless steel, aluminum, copper, or composite materials, this machine ensures that you can create fine grooves that meet the demands of both function and design.

With its high-quality construction, ease of use, and versatility, JIANMENG’s Horizontal V Grooving Machine is an indispensable tool for professionals in the sheet metal decoration and fabrication industries. As the demand for precision and high-end finishes continues to grow, this machine offers the perfect solution for meeting those needs while making the production process more efficient and affordable.