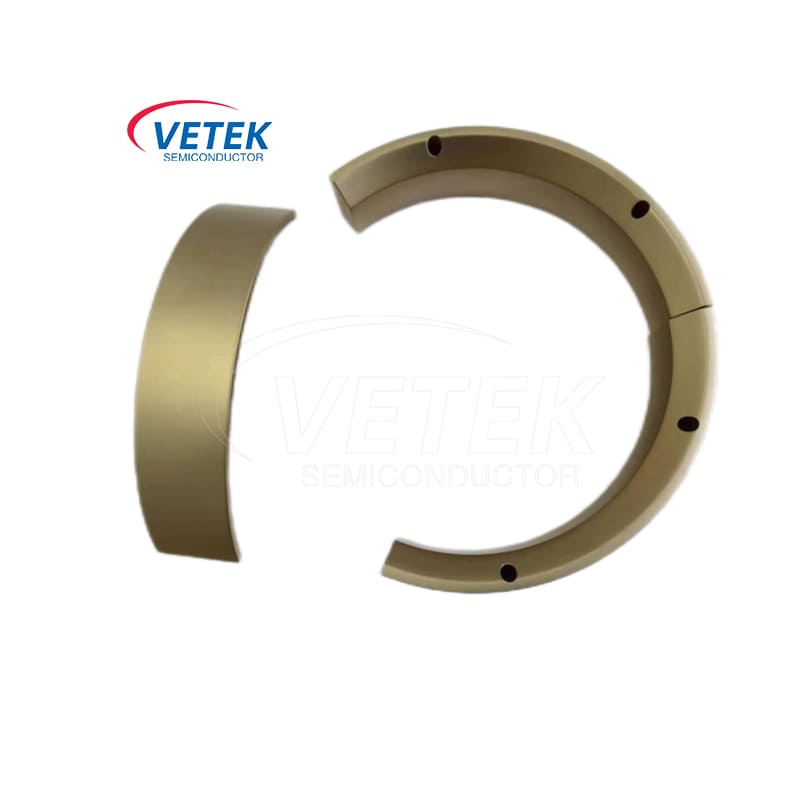

How Does the CVD TaC Coated Three-Petal Guide Ring Improve Operational Efficiency?

2025-01-14

Operational efficiency is a top priority in industries where downtime and equipment failure can result in significant costs. The CVD TaC coated three-petal guide ring is engineered to optimize performance, reduce maintenance, and enhance reliability. Here’s how this innovative component contributes to better efficiency in industrial systems.

1. Minimized Wear and Tear

The Tantalum Carbide coating applied through CVD technology creates an ultra-hard surface that resists abrasive and adhesive wear. This ensures the guide ring remains intact even under constant mechanical stress, reducing the need for frequent replacements.

2. Thermal Stability for High-Temperature Operations

In industries such as aerospace, metallurgy, and power generation, components often face extreme temperatures. The TaC coating provides unmatched thermal stability, allowing the guide ring to maintain its structural integrity and functionality even in environments exceeding 2200°C.

3. Enhanced Corrosion Resistance

Chemical exposure is a common challenge in industries like semiconductors and metal processing. The TaC coating resists corrosion from acids, alkalis, and other aggressive chemicals, ensuring long-term performance and reliability.

4. Improved Energy Efficiency

The low friction coefficient of the CVD TaC coating reduces energy losses caused by friction in moving parts. This not only improves system efficiency but also reduces operational costs over time.

5. Precision and Consistency

The three-petal design of the guide ring offers improved stability and support, while the precision of the CVD coating ensures consistent performance. This is critical in applications where even slight deviations can impact system effectiveness.

6. Reduced Maintenance Costs

Thanks to its durability and resistance to wear, corrosion, and temperature extremes, the CVD TaC coated guide ring requires less frequent maintenance. This translates to lower operational costs and minimizes downtime, ensuring uninterrupted productivity.

Key Industries Benefiting from This Technology

- Aerospace: High-temperature propulsion systems.

- Semiconductors: Precision components in manufacturing tools.

- Metal Processing: High-stress, high-heat environments.

- Energy: Components in turbines and reactors.

The CVD TaC coated three-petal guide ring is a game-changer for industries demanding high efficiency and reliability. Its ability to withstand extreme conditions, combined with its durability and precision, makes it a vital component for optimizing operations. Investing in such advanced technology not only enhances performance but also delivers long-term cost savings and operational stability.