Guiding the Way: How Large Diameter Stringing Blocks Accommodate Different Types of Conductors

2024-05-15

Large diameter stringing blocks are the unsung heroes of power line construction, guiding conductors with precision and reliability. But how do these versatile tools accommodate the diverse range of conductors used in electrical infrastructure projects? Let's delve into the intricacies of how large diameter stringing blocks adapt to various conductor types, ensuring smooth and efficient installations.

Understanding Large Diameter Stringing Blocks

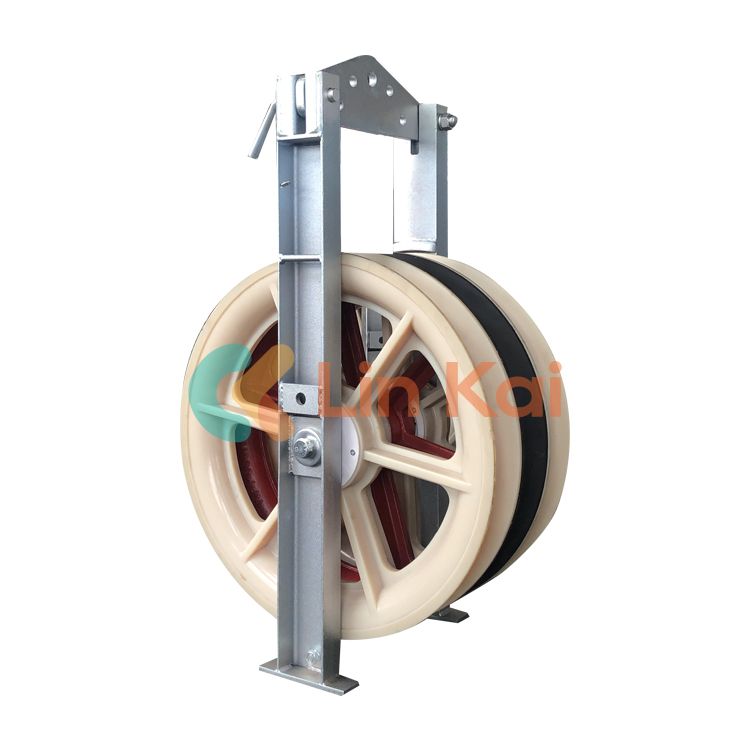

Before exploring their adaptability, let's grasp the fundamentals of large diameter stringing blocks. These robust devices are designed to support and guide conductors during installation, reducing friction and preventing damage to both the conductor and surrounding structures. They come in different sizes and configurations to accommodate various conductor diameters and project requirements.

Accommodating Different Conductor Types

1. Conductor Size: Large diameter stringing blocks are engineered to handle conductors of varying sizes. They feature grooved wheels or sheaves that match the diameter of the conductor, providing a snug fit that minimizes slippage and ensures smooth passage. Blocks with adjustable sheave diameters offer added flexibility, allowing operators to switch between different conductor sizes without changing equipment.

2. Conductor Material: Conductors can be made from a variety of materials, including aluminum, copper, and composite materials. Each material has its own unique properties and requirements. Large diameter stringing blocks must be compatible with these materials to ensure optimal performance and prevent damage. Blocks with non-metallic or coated sheaves are often used for aluminum and composite conductors to minimize scratching or abrasion.

3. Conductor Configuration: Conductors come in different configurations, such as bundled or single conductors, and may have varying degrees of flexibility. Large diameter stringing blocks are designed to accommodate these differences, with adjustable frame widths or multi-sheave configurations that can handle multiple conductors simultaneously. This versatility enables efficient stringing operations regardless of the conductor configuration.

4. Specialized Applications: In addition to standard conductors, large diameter stringing blocks may also be used for specialized applications, such as overhead ground wires or optical fiber cables. Blocks with specialized features, such as insulating sheaves or integrated ground wire rollers, are available to meet these specific needs while ensuring safe and efficient installation.

Ensuring Efficiency and Safety

Accommodating different types of conductors is essential for the efficiency and safety of power line construction projects. By providing a secure and reliable means of guiding conductors, large diameter stringing blocks help streamline installations and minimize the risk of damage or accidents.

Conclusion

Large diameter stringing blocks are versatile tools that play a crucial role in the construction and maintenance of power lines. Their ability to accommodate different types of conductors, from size and material to configuration and application, ensures that projects can be completed safely and efficiently, regardless of the specific requirements. With continued advancements in design and technology, these essential components will remain indispensable in the world of electrical infrastructure for years to come.