Ensuring Reliability in Harsh Environments with Slim PCB Power Relays

2024-07-10

Introduction

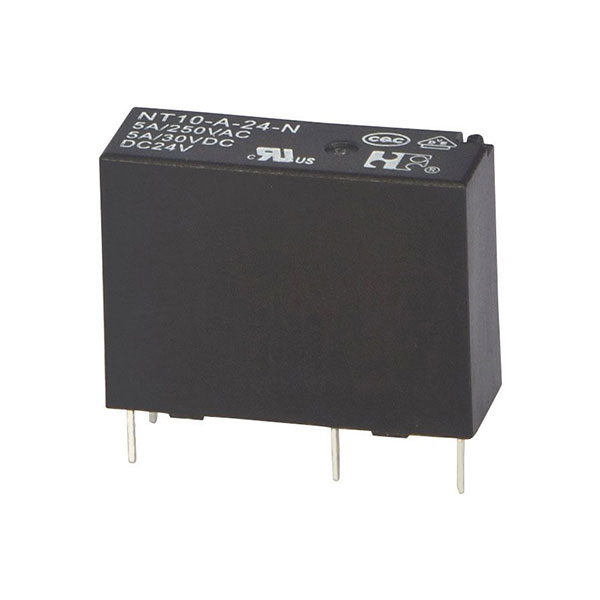

In today's advanced technological landscape, electronic devices are frequently exposed to harsh environments that challenge their durability and reliability. Slim PCB power relays, known for their compact size and robust performance, play a crucial role in maintaining the functionality of these devices. This blog will discuss how slim PCB power relays are designed to withstand harsh conditions and ensure reliable operation across various demanding applications.

The Challenges of Harsh Environments

Electronic devices operating in harsh environments face several challenges, including:

- Extreme Temperatures: High or low temperatures can affect the performance and longevity of electronic components.

- Moisture and Humidity: Exposure to moisture can lead to corrosion and short circuits, compromising the device’s reliability.

- Vibration and Shock: Mechanical vibrations and shocks can cause physical damage to components and affect their operation.

- Dust and Contaminants: Dust and other contaminants can interfere with the functioning of electronic parts and lead to failure.

Design Features of Slim PCB Power Relays for Harsh Environments

Slim PCB power relays are engineered with specific design features to combat these challenges and ensure reliable operation:

1. Temperature Resistance

- Wide Operating Range: Many slim PCB power relays are designed to operate within a wide temperature range, ensuring reliable performance in both high and low-temperature environments.

- Heat Management: Efficient thermal management systems are integrated into these relays to dissipate heat effectively, preventing overheating and ensuring stable operation.

2. Moisture and Humidity Protection

- Sealed Enclosures: Relays with sealed enclosures or protective coatings prevent moisture ingress, safeguarding internal components from corrosion and electrical shorts.

- Conformal Coating: Applying a conformal coating to the relay can further protect it from humidity and moisture, enhancing its durability in humid environments.

3. Vibration and Shock Resistance

- Robust Construction: Slim PCB power relays are constructed with durable materials and reinforced designs to withstand mechanical vibrations and shocks without compromising performance.

- Secure Mounting: Ensuring secure mounting on the PCB helps minimize the impact of vibrations and shocks on the relay’s operation.

4. Dust and Contaminant Protection

- Encapsulation: Encapsulated relays are protected against dust and contaminants, ensuring reliable operation even in dusty environments.

- Ingress Protection (IP) Rating: Many slim PCB power relays come with IP ratings that indicate their level of protection against dust and water, making it easier to select the right relay for specific environmental conditions.

Applications in Harsh Environments

Slim PCB power relays are crucial components in various applications that require reliable performance in harsh conditions:

1. Automotive Industry

- Engine Control Units (ECUs): Relays used in ECUs must withstand high temperatures, vibrations, and exposure to automotive fluids.

- Lighting Systems: Automotive lighting systems require relays that can endure temperature fluctuations and vibrations for reliable operation.

2. Industrial Automation

- Motor Controls: Industrial motor control systems rely on robust relays that can handle high power loads and operate in environments with dust, moisture, and vibrations.

- Factory Automation: Automated production lines use relays that must perform reliably under continuous operation and exposure to various environmental factors.

3. Renewable Energy Systems

- Solar Power Inverters: Inverters in solar power systems operate in outdoor environments, facing temperature extremes and moisture. Reliable relays ensure efficient power conversion and distribution.

- Wind Turbines: Relays in wind turbine control systems must withstand vibrations and harsh weather conditions to maintain consistent power generation.

4. Telecommunications

- Outdoor Base Stations: Telecommunications base stations exposed to outdoor conditions require relays that can handle temperature variations, moisture, and dust while maintaining reliable signal routing.

- Remote Communication Equipment: Equipment located in remote or harsh environments depends on durable relays to ensure continuous and reliable operation.

Testing and Certification

To ensure their reliability in harsh environments, slim PCB power relays undergo rigorous testing and certification processes:

- Environmental Testing: Relays are subjected to tests that simulate extreme temperatures, humidity, vibrations, and shocks to verify their performance and durability.

- Industry Standards: Compliance with industry standards and certifications, such as UL, IEC, and RoHS, ensures that the relays meet stringent quality and safety requirements.

Conclusion

Slim PCB power relays are essential components in electronic devices operating in harsh environments. Their robust design features, such as temperature resistance, moisture protection, vibration resistance, and dust protection, ensure reliable performance across various demanding applications. By understanding the challenges of harsh environments and selecting relays that meet the required specifications, designers and engineers can enhance the reliability and longevity of their electronic systems. Investing in high-quality slim PCB power relays is a crucial step towards achieving consistent and dependable performance, even in the most challenging conditions.