Ensuring Operator Safety: Key Features of the Fire Hazard Testing Apparatus Glow Wire Tester

2024-07-03

Fire hazard testing is crucial in evaluating the safety and performance of materials and products under fire conditions. The Glow Wire Tester is a widely used apparatus for such tests, especially in assessing the flammability of plastics and other materials used in electrical and electronic devices. Given the inherent risks involved in fire hazard testing, ensuring operator safety is paramount. This blog explores the essential safety features incorporated into the Fire Hazard Testing Apparatus Glow Wire Tester to protect operators during testing.

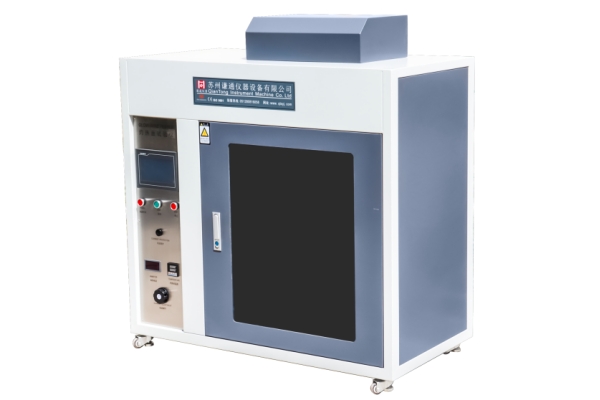

1. Enclosed Testing Chamber

One of the primary safety features of the Glow Wire Tester is its fully enclosed testing chamber. This enclosure contains the heat and any potential flames within a controlled environment, preventing accidental exposure to the operator. The chamber is typically made from heat-resistant materials and includes a transparent window or screen, allowing operators to observe the test without direct exposure to the hazards.

2. Automatic Shutdown Mechanism

To further enhance safety, the Glow Wire Tester is equipped with an automatic shutdown mechanism. In the event of an unexpected issue, such as overheating, electrical faults, or any other malfunction, the system automatically shuts down to prevent accidents. This feature ensures that the apparatus does not pose a danger to the operator or the testing environment.

3. Temperature Control and Monitoring

Precise temperature control and monitoring are critical for both the accuracy of the tests and operator safety. The Glow Wire Tester includes advanced temperature control systems that maintain the desired test temperatures accurately. Additionally, real-time temperature monitoring with alarms alerts the operator if temperatures exceed safe limits, allowing for immediate intervention.

4. Fume Extraction System

During glow wire tests, the materials being tested can emit potentially harmful fumes. To protect operators from inhaling these fumes, the apparatus is equipped with a fume extraction system. This system effectively removes smoke and fumes from the testing chamber, filtering them to ensure clean air is expelled. This feature is essential in maintaining a safe and healthy working environment.

5. Safety Interlocks

Safety interlocks are mechanical or electronic devices that prevent the apparatus from operating unless specific safety conditions are met. For instance, the Glow Wire Tester may include interlocks that ensure the testing chamber door is securely closed before the test can begin. This prevents accidental exposure to high temperatures or flames.

6. Insulated Handling Tools

Operators often need to handle hot components or materials during and after testing. The Glow Wire Tester typically comes with insulated handling tools, such as tongs and gloves, to protect operators from burns. These tools are designed to withstand high temperatures, allowing safe manipulation of test samples.

Conclusion

The Glow Wire Tester is an indispensable tool in fire hazard testing, providing critical insights into the flammability and safety of materials. However, the inherent risks associated with fire testing necessitate robust safety measures. By incorporating features such as an enclosed testing chamber, automatic shutdown mechanisms, temperature control, fume extraction, safety interlocks, insulated handling tools, and comprehensive training, the Glow Wire Tester ensures the highest level of operator safety. These safety features not only protect operators but also contribute to the reliability and accuracy of the test results, ultimately enhancing the safety of the products being tested.