Some common metal CNC milling parts that can be produced

2023-10-18

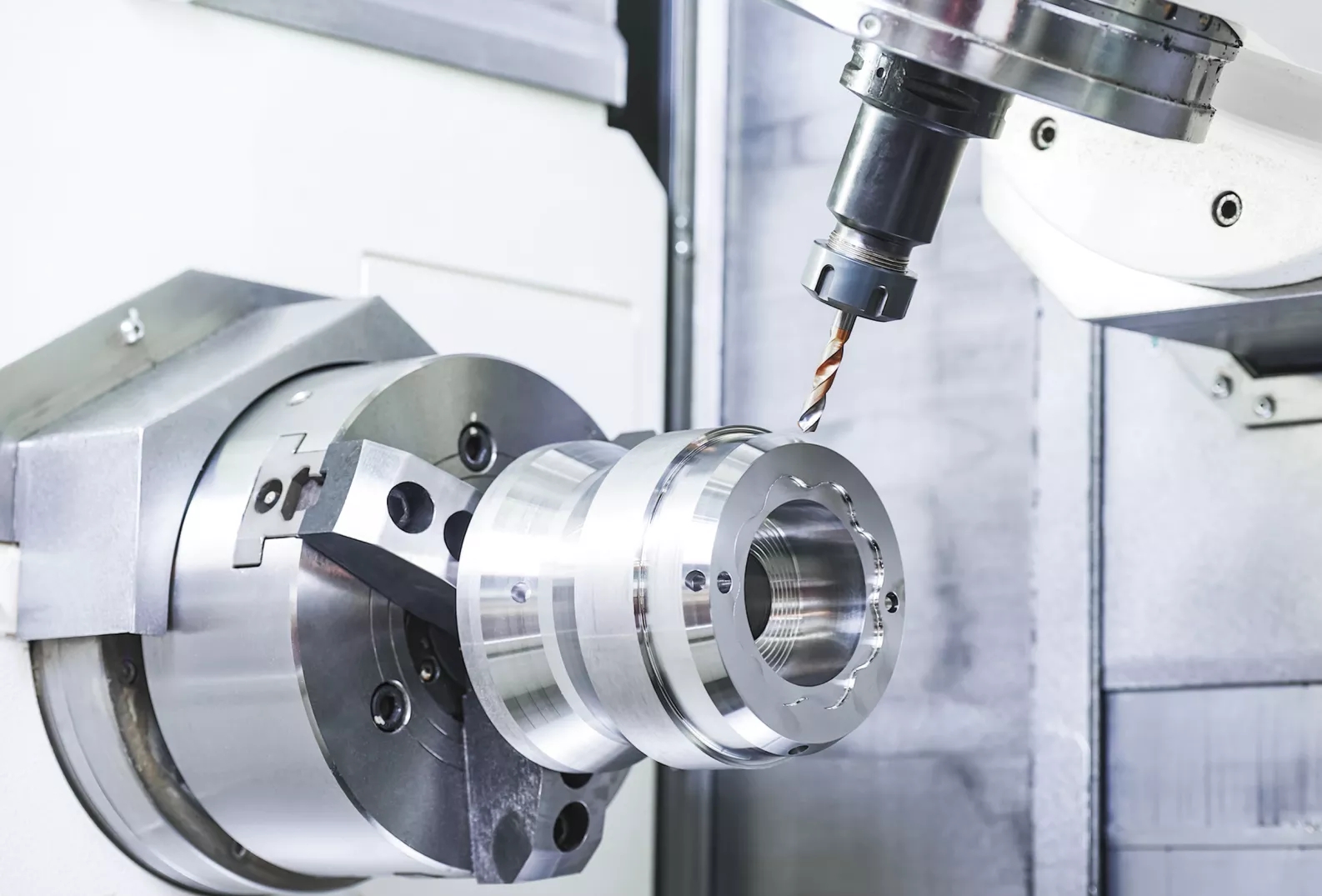

Metal CNC milling is a machining process that uses computer numerical control (CNC) machines to remove material from a metal workpiece and create precise and complex parts. CNC milling machines employ rotating cutting tools to remove material, following programmed instructions to achieve the desired shape and dimensions.

Here are some common metal CNC milling parts that can be produced:

1. Prototypes: CNC milling is often used to create prototypes of metal parts. Prototypes allow designers and engineers to test and validate their designs before moving into full-scale production.

2. Components: CNC milling is commonly employed to manufacture individual metal components for various applications. These components can range from simple brackets and housings to intricate gears, connectors, and shafts.

3. Aerospace Parts: CNC milling is extensively used in the aerospace industry to manufacture critical components like aircraft engine parts, landing gear components, wing sections, and structural components. These parts often require high precision, tight tolerances, and complex geometries.

4. Automotive Parts: CNC milling is utilized in the automotive industry to produce a wide range of metal parts, including engine components, transmission parts, suspension components, brackets, and housings. The process allows for precise machining of intricate features required for optimal performance and durability.

5. Medical Implants: CNC milling is employed in the production of various medical implants, such as hip and knee replacements, spinal implants, and dental implants. These parts often require biocompatible materials and precise machining to ensure compatibility and functionality within the human body.

6. Electronic Enclosures: CNC milling is used to manufacture metal enclosures for electronic devices, such as computer chassis, server racks, and control panels. The process enables the creation of intricate designs, precise cutouts for connectors and switches, and optimal heat dissipation features.

7. Tooling and Fixtures: CNC milling is also employed to create tooling and fixtures used in manufacturing processes. These include jigs, molds, dies, and custom workholding devices that aid in the production of other parts.

The specific design and production process for metal CNC milling parts can vary depending on the requirements of the part and the CNC machine being used. It's crucial to work with experienced CNC machining professionals or consult with manufacturing engineers to ensure the best results for your specific metal parts.