What is the difference between single and double hydraulic cylinder?

2023-10-18

The difference between single and double hydraulic cylinders lies in the number of cylinders used in the hydraulic system and how they operate. Here's an explanation of each type:

1. Single Hydraulic Cylinder:

A single hydraulic cylinder system consists of a single cylinder that is connected to a hydraulic pump or power source. When hydraulic fluid is supplied to the cylinder, it creates a pushing or pulling force to move the load or perform a specific task. The piston inside the cylinder moves in a linear motion, extending or retracting to generate force.

Single hydraulic cylinders are commonly used in applications where a straightforward linear motion is required, such as lifting or lowering objects, pushing or pulling loads, or providing simple linear actuation. They are relatively simple in design and operation, and their force output is determined by factors such as the cylinder size, hydraulic pressure, and piston diameter.

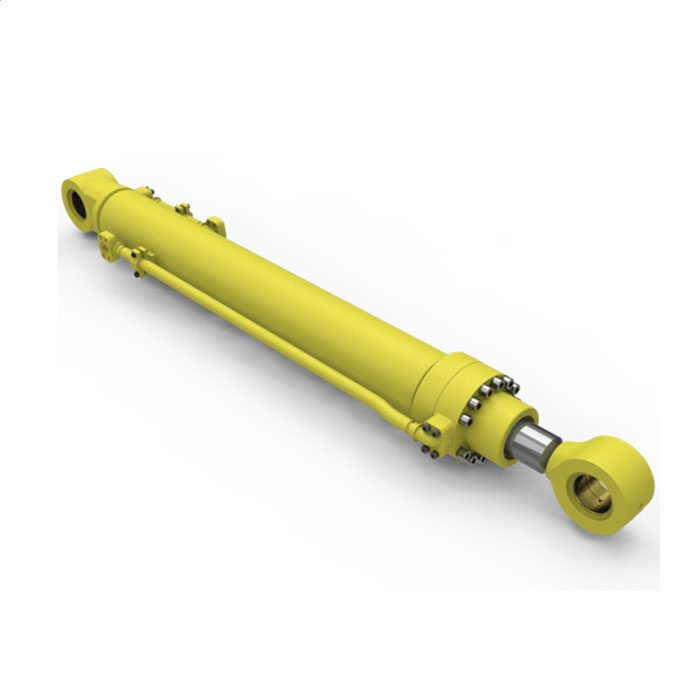

2. Double Hydraulic Cylinder:

A double hydraulic cylinder system consists of two interconnected cylinders that work in tandem. The cylinders are typically arranged in a parallel or series configuration, with hydraulic fluid being supplied to both cylinders simultaneously. When pressure is applied, it generates force in opposite directions in the two cylinders.

The double hydraulic cylinder system provides more complex motion and force capabilities compared to a single cylinder. By controlling the flow of hydraulic fluid to each cylinder, it allows for synchronized movement, equal force distribution, or differential force application. This can be useful in applications where precise control of motion, balancing of loads, or synchronized movement of multiple components is required.

Double hydraulic cylinders are commonly used in various applications, including heavy machinery, construction equipment, hydraulic presses, lifting systems, and more. They provide enhanced force output, load balancing, and flexibility in motion control.

It's important to note that the choice between a single or double hydraulic cylinder system depends on the specific requirements of the application. Factors such as load capacity, desired motion control, force distribution, and system complexity will influence the selection. Consulting with a hydraulic system engineer or expert can help determine the most suitable option based on the intended use and performance requirements.