Information about Automatic Plug Assembly Machine

2023-10-18

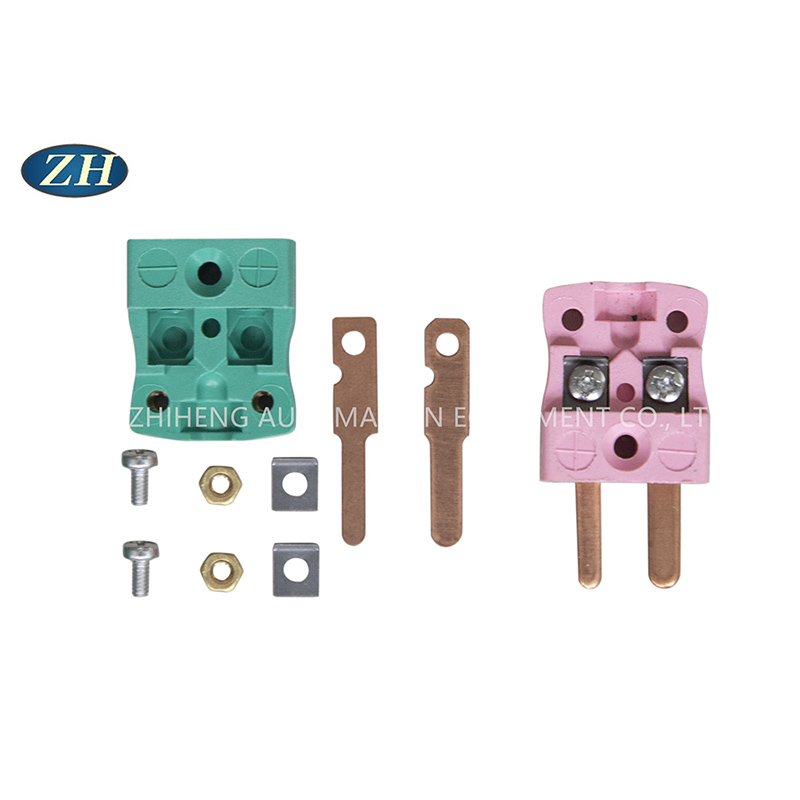

An automatic plug assembly machine is a specialized piece of equipment used in manufacturing and assembly processes to automate the task of assembling plugs, connectors, or similar components. These machines streamline the production process, improve efficiency, and ensure consistent and accurate assembly. Here's some information about automatic plug assembly machines:

Assembly Process Automation: Automatic plug assembly machines are designed to automate the various steps involved in assembling plugs or connectors. This includes tasks such as inserting pins or contacts, securing components, crimping wires, and performing quality checks.

Key Components and Features:

- Feeding Mechanism: These machines often include feeding mechanisms that deliver individual components, such as pins, contacts, and wires, to the assembly station.

- Assembly Stations: The machine is equipped with stations for performing different assembly tasks, such as inserting pins, crimping, and securing components in place.

- Guiding Systems: Precision guiding systems ensure that components are positioned accurately during assembly.

- Crimping Mechanisms: Crimping tools are integrated to secure wires or contacts in place with consistent force and accuracy.

- Quality Checks: Some machines include sensors or vision systems to inspect assembled plugs for correct alignment, proper contact, and other quality parameters.

- Control System: Modern machines are equipped with user-friendly control interfaces that allow operators to set parameters, monitor the assembly process, and make adjustments as needed.

Benefits:

- Efficiency: Automatic plug assembly machines significantly speed up the assembly process, reducing production time and increasing output.

- Consistency: Automation ensures that each plug or connector is assembled with consistent quality and precision, minimizing variations between units.

- Labor Savings: By automating the assembly process, companies can reduce labor requirements and allocate human resources to more skilled tasks.

- Reduced Errors: Automation reduces the chances of human errors that can occur during manual assembly, leading to fewer defects and rework.

- Scalability: These machines can be designed to handle different plug or connector types, making them adaptable to changing production needs.

- Improved Ergonomics: Automation reduces repetitive strain on workers, improving workplace ergonomics and reducing the risk of injuries.

Applications:

Automatic plug assembly machines are used across various industries where plugs, connectors, and terminals are an integral part of the product. Some common industries and applications include:

- Electronics: Assembly of connectors for cables, PCBs, and electronic devices.

- Automotive: Assembly of wiring harnesses, connectors for vehicle components.

- Appliances: Assembly of plugs and connectors for household appliances.

- Aerospace: Assembly of connectors for avionics and aircraft systems.

- Telecommunications: Assembly of connectors for cables and communication equipment.

Considerations:

- Machine Customization: Machines can often be customized to accommodate different plug types, sizes, and assembly processes.

- Maintenance: Regular maintenance is important to ensure the machine operates smoothly and maintains accuracy.

- Initial Investment: There is an upfront cost associated with acquiring and installing an automatic plug assembly machine.

- Training: Operators need training to operate and maintain the machine effectively.

Automatic plug assembly machines play a vital role in improving production efficiency, quality, and consistency in industries that rely on connectors and plugs. When considering the implementation of such a machine, companies should assess their production requirements, the types of plugs they work with, and the potential benefits of automation.